This Website uses cookies to ensure you get the best experience on our website. Read More

Self-Supporting & Guy Capable, Fully Automated Heavy-Duty Tower Systems

- Greatest self-supporting and guy capable survivability of any comparable lattice steel telescopic structure – No guy wires required at any elevation to a maximum wind-load and design wind velocity

- Certified compliance with the ANSI TIA/EIA 222-G Standard – Tower Legs: seamless, mechanical tubing – HSS-ASTM DOM 1026 alloy/A513 to 95Ksi yield strength – solid rod bracing-ASTM A36, 100% hot-dipped galvanized per ASTM A123

- Elevations to 130’ (39.6m) AGL; Configurations with wind survivability in excess of 130 mph (209/kph); Tower load Capacity to 550 lbs (250 kg) standard – upgrade to 650 lbs (295 kg); 120-220VAC/60-50Hz Configurations

- MIL-STD-810E, MIL-STD-1472, MIL-STD-454 used as guides in design and manufacturing processes; Certified to AWS D1.1; ISO 9001:2015 Quality Registration

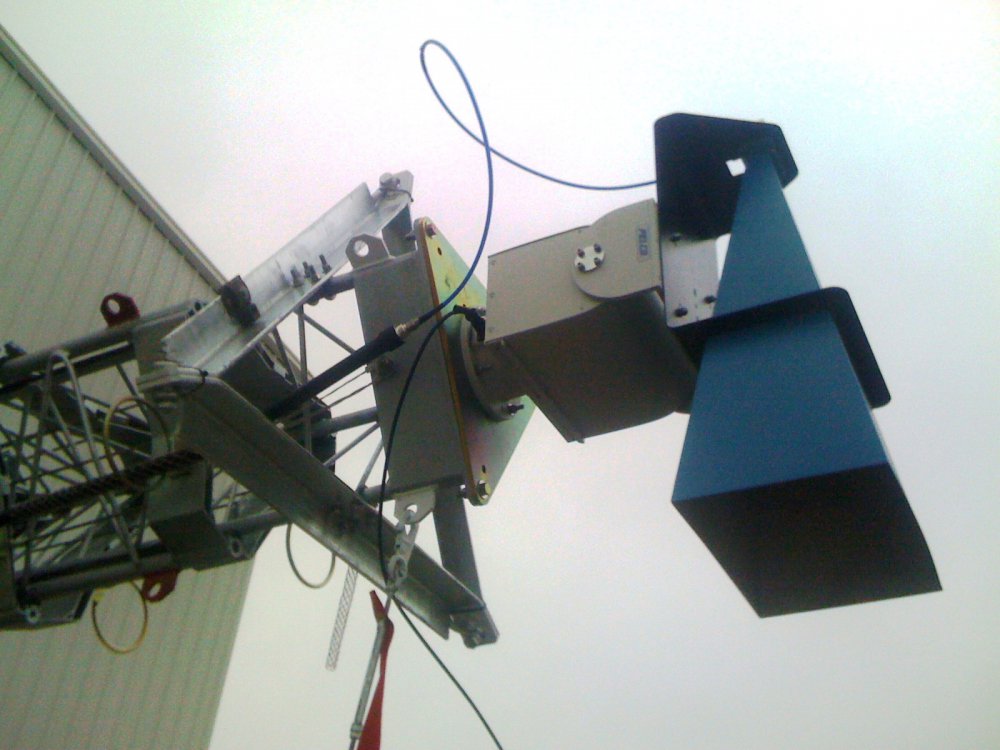

- Direct drive, extreme environment tower operating systems – No exposed belts or chains – Aircraft quality tower cables, stainless pulleys, solid-state circuitry – Integrated Safety Features throughout

- Extended tower and transport lock mechanisms – Redundant cabling for increased safety – LED warning and tower operating lamps

Photos

View More »

View More »